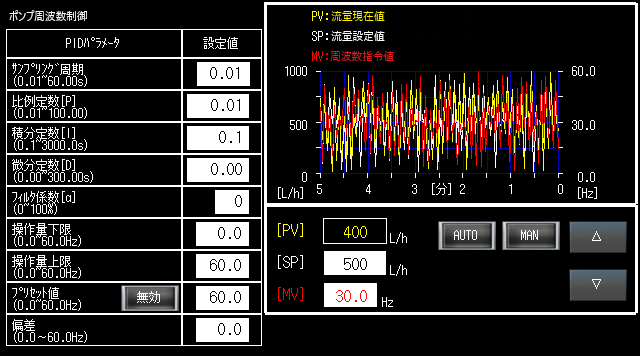

PID Control of Liquid Flow Using Mitsubishi Q Series PLC

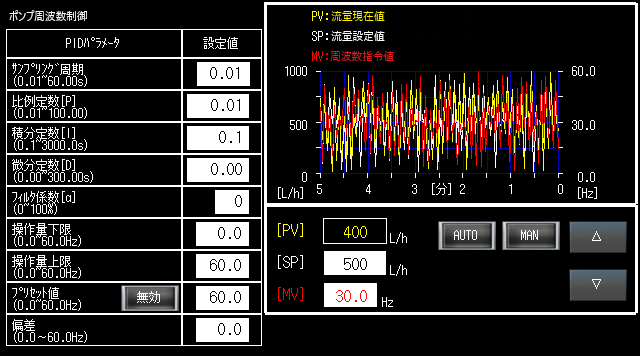

Previously, we introduced the method of PID control for a heater using a Mitsubishi FX Series PLC. This time, we will explain how to perform PID control of liquid flow using a Mitsubishi Q Series PLC. The PLC used is Q03UDECPU, with the current flow rate input taken via Q68ADI, and a Mitsubishi FR Series inverter used to adjust the pump frequency.

Contents

Inputting the Current Flow Rate into the PLC

To perform flow control, the current flow rate must be input into the PLC. In this case, a Keyence flow sensor with a 4-20mA output was connected to Q68ADI, allowing the current flow rate to be read.

Setting the Initial Device Number for PID Control

The [PIDINIT] command is used to specify the starting device number for PID control.

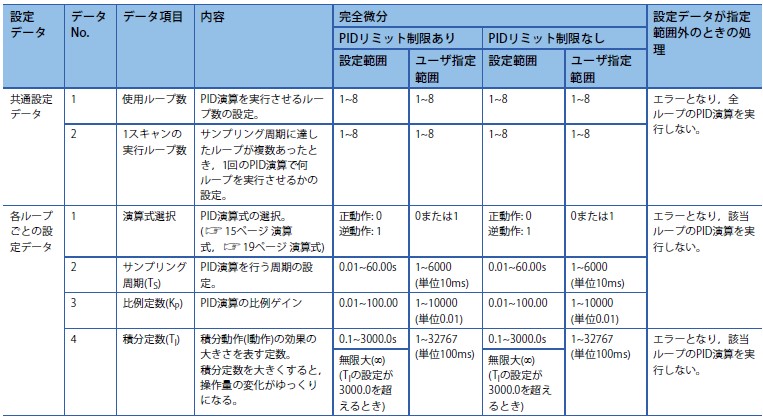

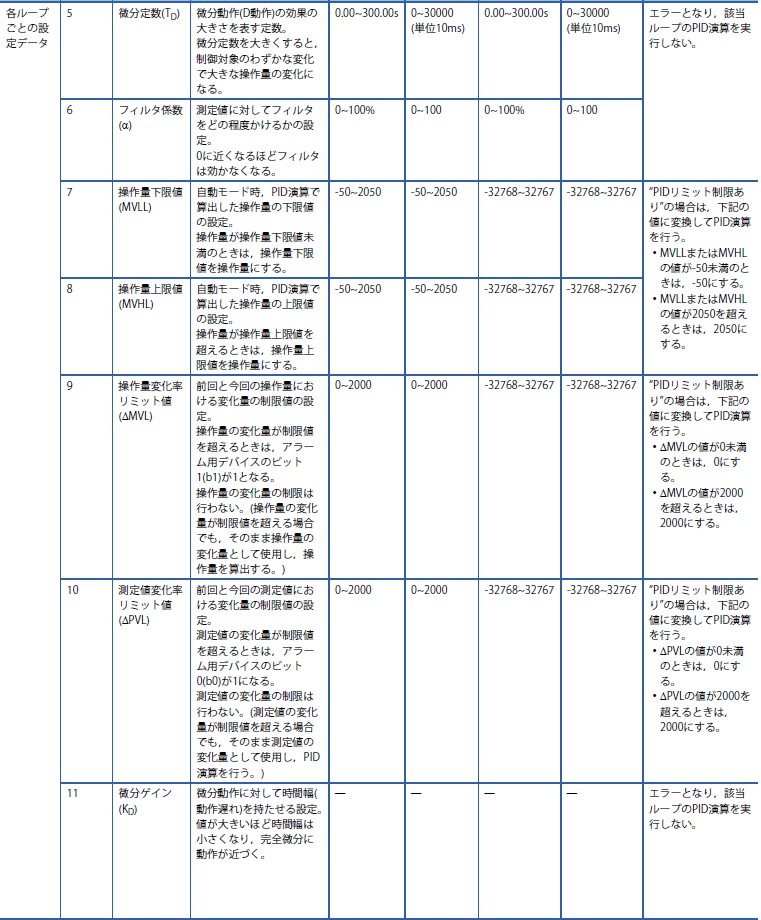

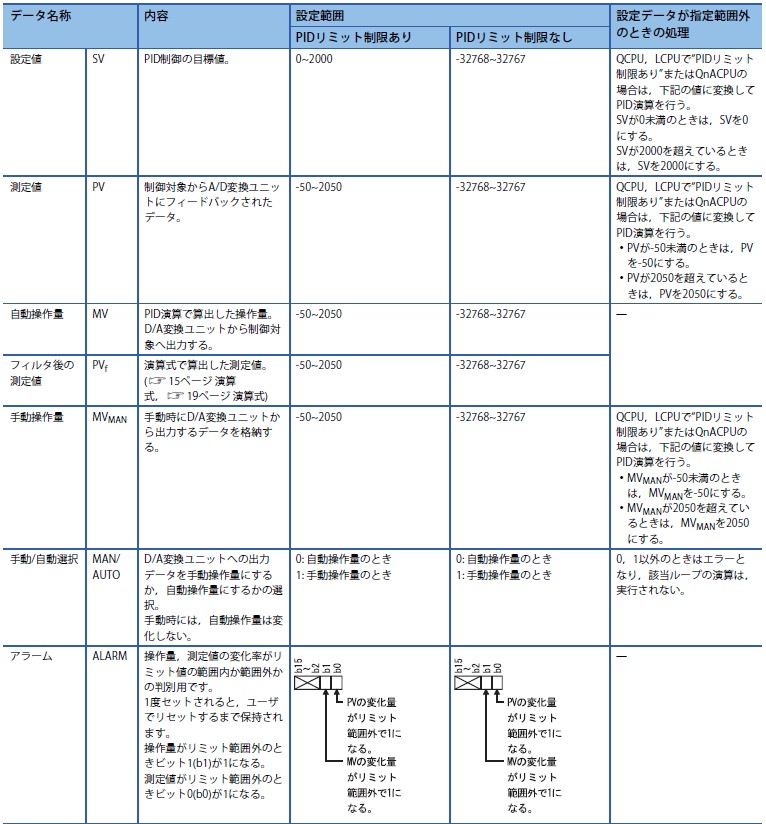

Configuring Parameters for PID Control

The [PIDPRMW] command is used to set the parameters for PID control.

P Value (Proportional Control)

・Function: Outputs a control value proportional to the current error.

・Characteristics: The larger the error, the stronger the correction. However, residual error (offset error) may occur.

I Value (Integral Control)

・Function: Accumulates past errors and corrects over time.

・Characteristics: Eliminates residual error but may cause oscillations due to excessive correction (integral windup).

D Value (Derivative Control)

・Function: Controls based on the rate of change of the error, enabling quick response and suppression of oscillations.

・Characteristics:Sensitive to noise, so imperfect differentiation (low-pass filtering) is commonly used.

Controlling Flow Rate Using PID Commands

The [PIDCONT] command is used to calculate the output operation amount (frequency) based on the current flow rate, adjusting the inverter frequency to control the flow rate.

Summary

In a previous system with similar equipment, a typical P control was used, where:

- If the set flow rate ≤ current flow rate, the pump frequency was gradually decreased.

- If the set flow rate ≥ current flow rate, the pump frequency was gradually increased.

However, in this case, the goal was to maintain a stable flow rate, so PID control was implemented to achieve this.

Although tuning the parameters to stabilize the flow rate takes time, once the optimal settings are found, the flow rate remains stable, making this method highly practical.