PLC Remote Maintenance Test [1] Monitor and change the program of a PLC at a remote location.

When it becomes necessary to monitor the PLC programs of facilities and equipment installed in remote locations, or to investigate the programs, it is usually necessary to visit the site to take action, but due to the current impact of the new coronavirus infection, it may become difficult to visit in the future.

Remote work is now being actively used in the business scene, and for the reasons mentioned above, I believe that a system that allows for remote maintenance of facilities and equipment will also be necessary.

In this project, we will monitor the program of a PLC in a remote location and test to change the program.

Contents

Advantages and challenges of performing PLC remote maintenance of remotely located facilities and equipment

Advantage

・Can quickly respond to sudden problems with facilities and equipment, and investigate programs without having to visit the site.

・Reduce travel costs and travel time for on-site visits.

・Change the operation and timers of facilities and equipment in operation.

challenges

・Cannot deal with physical failure of PLC.

・Difficult to use the customer's internal network.

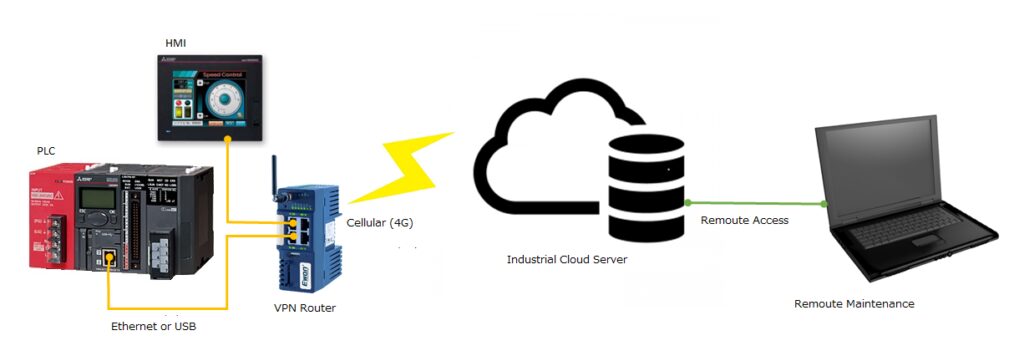

Connect to the facility's internal network via the Internet through a VPN gateway router

By using an industrial VPN gateway router and LTE line, the PLC can be accessed without using the customer's internal network.

Test video of PLC Remote maintenance

We set up the PLC and test equipment in our office in Gunma Prefecture, and monitored and changed the program via the Internet from Aichi Prefecture, where I visited on a business trip.

Test video of program change from remote location

The time required for writing was about 34 seconds. You can see that the lamp pattern actually changed in about 23 seconds.

Summary of PLC remote maintenance test

In this test, we were able to remotely monitor the PLC connected to the router with a LAN cable and confirm that we could change the program. In addition, once the connection between the PC and the router is established via the Internet, the operation can be performed as if the PC and PLC were connected directly. Although the connection time and writing time are a little longer than those of direct connection, it is possible to go to a remote location.