Simple CPU communication by Ethernet connection between Mitsubishi Q PLC and FX PLC

The data communication method between Mitsubishi's Q series PLC and FX series PLC is simple CPU communication by Ethernet connection.

Contents

What is simple CPU communication?

It is a function that allows Ethernet-connected PLCs to communicate with each other and send/receive device data without programming, with just a simple setting using GX Works2 or 3.

Example of simple CPU communication between Q PLC and FX PLC

This is an example of simple CPU communication between Q PLC and FX PLC that we recently performed.

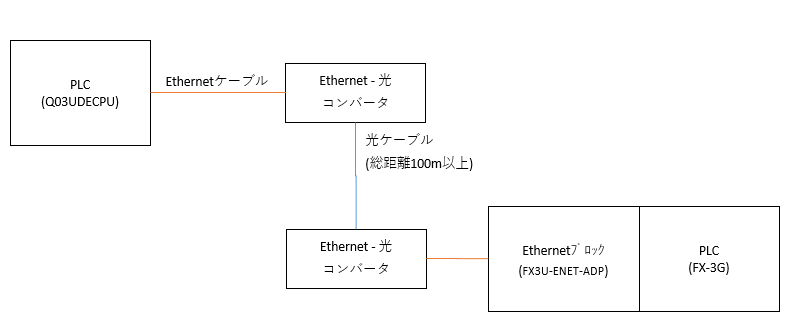

Since the total distance between the installed devices was more than 100m, we configured the Ethernet cable to be converted to an optical cable in the middle.

Equipment configuration

1.Equipment used

・Q series PLC: Q03UDECPU (built-in Ethernet)

・FX series PLC: FX3G (Ethernet block: FX3U-ENET-ADP)

・Ethernet to Optical Converter

2.Equipment configuration

How to set up the Q PLC side

1.Parameter setting

Set the IP address of the Q PLC.

2.Simple CPU communication settings

Configure the settings for simple CPU communication.

Set the source and destination devices and the number of points for the Q PLC side and the FX PLC side, respectively.

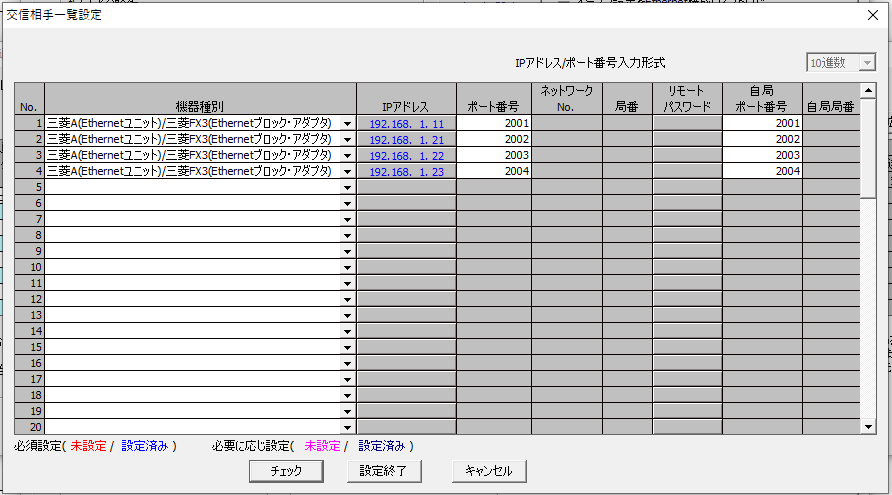

3.Set up a list of contacts

Set up the other device (PLC) for communication. Set the IP address and port number of the other device.

In this case, the settings are for four PLCs since we are communicating with one Q PLC and four FX PLCs.

How to configure the FX PLC side

1.Parameter setting

Set the IP address of FX PLC in "FX Parameter Setting" - "Ethernet Port Setting". In this case, CH2 is used because a special communication adapter is installed separately, but if you use only Ethernet block, CH1 is OK.

2.Ethernet port open setting

Set the open setting of the Ethernet port of FX PLC. Set the protocol to UDP, the open method to MC protocol, and the port number to the same port number as the one set in Q PLC communicating partner list setting.

Check communication between PLCs

After all the settings are completed, transfer the settings to the PLC. After the transfer, restart the PLC and check the communication with the device monitor.

We were able to communicate without any problems.

Simple CPU communication between Q PLC and FX PLC summary

The advantages of using simple CPU communication between PLCs are

・Communication can be established with only simple settings.

・More data can be transferred than with CC-Link.

・Communication can be done with a single Ethernet cable.

・Debugging (monitoring) of PLCs connected from a single location via a hub is possible.

These are some examples.

The parameter setting method on the FX PLC side is a little different from the setting method for simple CPU communication between Q series, but we were able to establish communication just by setting the GX Works2 parameters and simple CPU communication settings.

There are many examples of simple CPU communication between Q PLCs on the Internet, but there don't seem to be many examples of Q PLCs and FX PLCs, so we hope you find them useful.